The Wonderful Loaf at Miller’s Thumb Bakery honors the city’s rich baking history by channeling the spirit of an iconic American brand.

The Wonderful Loaf at Miller’s Thumb Bakery honors the city’s rich baking history by channeling the spirit of an iconic American brand.

December 16, 2024

Photo illustration by Matt Wheeland for Civil Eats, featuring a Wonderful Loaf from Miller’s Thumb Bakery & Cafe in Buffalo, NY.

While most Buffalonians are fast asleep, Stephen Horton of Miller’s Thumb Bakery begins milling fresh flour at 3:30 a.m. every morning. For the next two hours, he carefully feeds beadlike kernels of New York State–grown Glenn and Warthog wheat from 50-pound bags into the bakery’s custom-made stone mill as flour sprays in powdery sheets from the opposite side, like a snowblower.

Expand your understanding of food systems as a Civil Eats member. Enjoy unlimited access to our groundbreaking reporting, engage with experts, and connect with a community of changemakers.

Already a member?

Login

Freshly milled flour is part of Buffalo’s legacy. For a century, the city was a hub of America’s grain trade, as well as its flour milling and bread manufacturing. Horton’s flour comprises the base of his bagels, buns, sweet rolls—and the bakery’s Wonderful Loaf, an homage to Wonder Bread that Horton and his business and life partner, Jill Colella, conceived as a flagship product when they opened Miller’s Thumb in 2022.

Long before Buffalo was celebrated for its eponymous hot wings and roast beef on a kummelweck roll, the city’s food economy centered around grain. But in the latter half of the 20th century, as the city’s once-flourishing shipping industry slowly deteriorated, Buffalo’s legacy as a bread-baking and milling town became a forgotten footnote. Among the remnants of the city’s golden age are the towering rows of abandoned grain elevators whose hollowed-out carcasses still inhabit the shores of the Buffalo River, a haunting reminder of the city’s glorious agrarian past.

Horton’s freshly milled flour comprises the base of the bakery’s Wonderful Loaf, an homage to Wonder Bread.

Colella is a proud Buffalo native and the creative force behind Wonderful Loaf. She moved back home from Minneapolis with Horton in 2019 after the two began devising a plan for a bakery there. “I was always jealous of Wonder Bread when I was kid,” she says. “My mom would buy this other brand, Sunbeam, which was like Hydrox cookies instead of Oreos for me.” Colella saw a need in the community for an affordable everyday sandwich bread, like the recognizable brands of her youth. “When Dad went to the store, he would buy the name brand and we would use the leftover Wonder Bread bags to line our snow boots,” she adds.

Colella and Horton were keenly aware that a scant six miles from their bakery, an abandoned Wonder Bread factory, active from 1925 to 2004, still stood, derelict from two decades of neglect. In its heyday, the facility showcased the innovative automated manufacturing methods of Wonder Bread, one of the first commercial breads to be sold pre-sliced.

With Wonderful Loaf, Colella saw an opportunity to honor Buffalo’s bread-baking legacy while eschewing the highly processed ingredients that strip industrial breads of their nutritional value and flavor. “If Wonder Bread was supposed to be this scientific miracle, then we felt like we could make it even more wonderful by using better flour, better methods, and cleaner ingredients,” Colella says.

From a distance, it’s difficult to make out the two words that once stood atop the roof of the abandoned five-story factory building on Fougeron Street, bounded by Barthel and Urban streets on Buffalo’s industrial east side. Despite the missing characters, if you stare long enough at the signage, you can deduce that it once read “WONDER BREAD” in giant block lettering.

Aside from the 56-acre Martin Luther King, Jr. Park, originally called The Parade and designed in 1874 by Fredrick Law Olmsted of Central Park fame, there isn’t much within a five-block radius of the moribund factory. Before the plant unceremoniously closed 20 years ago, the yeasty aroma of freshly baked Wonder Bread permeated the neighborhood; in its heyday, the factory could produce 100,000 loaves, 50,000 cakes, and 20,000 rolls every day. Now, the windows along the perimeter of the blond brick building, framed by Roman-inspired arches, are mostly all blown out and boarded up, and the interior of the factory is ransacked and riddled with graffiti.

“The building is a classic example of a scientific and sanitary bakery inspired by the Pure Foods movement in the early 20th century,” says Chris Hawley, a local urbanist and preservationist who authored the application to award the Wonder Bread Factory local landmark status, which was approved in 2018. “These structures were an outgrowth of progressivism and the notion that science can join hands with agriculture to produce healthier foods, before we learned better that some of these foods weren’t so healthy after all.”

Wonder Bread didn’t originate in Buffalo. The product was first manufactured by the Taggart Baking Company in Indianapolis in 1921. It wasn’t until the Buffalo-based Continental Baking Company (formerly Ward & Ward Incorporated), which built the Fougeron Street facility in 1914, acquired Taggart in 1925 that it began baking Wonder Bread in Buffalo. By 1928, after a series of aggressive acquisitions, the Continental Baking Company became the largest commercial baking operation in the United States.

According to The New York Times, Continental Baking Company’s profits in 1950 neared record highs with sales of more than $150 million, primarily fueled by the popularity of Wonder Bread and Hostess baked goods. Wonder Bread has since had multiple owners, and although it’s no longer the household staple it once was, the brand lives on, generating half a billion in sales in 2022 for its current owner, Flowers Foods.

“Wonder Bread is an iconic American product,” says Hawley, stressing the importance of preserving the deteriorating building. “It’s as important as Coca-Cola or M&M’s in American food history. It helps tell the story of America in the 20th century.”

Before Miller’s Thumb Bakery opened in 2022, Horton spent months researching his recipe for Wonderful Loaf, creating over a dozen failed prototypes before arriving at the finished product. Working with freshly milled flour can create challenges to achieving a consistent bake. “The flavor profiles are more unique and complex than commercially created flour,” says Horton, “but there are also more natural oils present in freshly milled flours that interfere with gluten structure, and using them doesn’t allow for the same volume.” The biggest challenge was replicating Wonder Bread’s signature squishiness.

To increase volume, Horton adds 20 percent King Arthur Sir Galahad flour to the freshly milled flour base as well as a small amount of fava-bean flour from Bob’s Red Mill as an “improver” to get even more lift. Horton explains that natural enzymes in fava-bean flour create peroxide, which reinforces gluten structure and builds volume in the rise. Using commercial yeast further encourages leavening. To this mix, Horton adds naturally fermented levain (sourdough starter), eggs, and a hint of butter to achieve a more tender crumb and more flavorful crust.

Wonder Bread, on the other hand, is enriched with vitamin and mineral additives like iron, niacin, and riboflavin, and contains preservatives like calcium propionate that are used to slow spoilage. Because industrial baked goods like Wonder Bread are made with refined wheat flours that are stripped of their nutrients by commercial milling methods, the dough needs to be enriched before baking. Enriched breads also lack the fiber content of breads made from freshly milled whole-grain flour, which contains more bran—like Wonderful Loaf.

Mass-produced commercial breads also often contain traces of glyphosate, the most widely used synthetic herbicide. Those levels are generally considered safe by the U.S. Food and Drug Administration, although glyphosate is connected to health risks at higher exposure levels experienced by people who spray it regularly. The freshly milled flour at Miller’s Thumb Bakery—made from Farmer Ground USDA-certified organic whole wheat—is glyphosate-free. (According to King Arthur, its Sir Galahad flour is a non-organic product which may contain glyphosate up to the federally mandated limits.)

Among the remnants of Buffalo’s golden age are the towering rows of abandoned grain elevators whose hollowed-out carcasses still inhabit the shores of the Buffalo River.

With Wonderful Loaf, the plan was always to create an affordable and more wholesome workhorse bread that locals could count on, the way they once did with the ubiquitous Wonder Bread. “Accessibility was always key,” Colella says. “We knew that if we could bring people in with certain products, that those could be a Trojan Horse for things that Steve is very passionate about—like true sourdough and 100 percent rye bread.”

To settle on the right price point, the couple canvassed local supermarkets. “We looked at grocery stores in our area, like Wegman’s, and we wanted to keep our breads similarly priced or perhaps even lower,” says Colella. “Wonder Bread here typically costs between $4.50 and $5. We charge $5.95 for ours, and we also sell it by the half loaf. The price hasn’t changed since we opened.” Colella says the bread, sold entirely at the bakery, is most popular among families with young children and local seniors looking for a softer alternative to the bakery’s crustier sourdoughs.

A sign over the Wonderful Loaf reads: “Like the icon but better.” Horton’s version replicates the airiness of the original but with a deeper, wheatier flavor. He purposely bakes the bread in a pan with slightly wider dimensions than Wonder Bread, preferring the broader width to make more substantial sandwiches. In a peanut butter and jelly sandwich, Wonderful Loaf is both nostalgia-inducing and delicious—the platonic ideal of Wonder Bread without the baggage.

Miller’s Thumb’s success with products like Wonderful Loaf benefits the city’s economy, but it also boosts the local grain economy as well. Horton and Colella embrace their responsibility for supporting local farmers. They buy Farmer Ground grains sourced almost exclusively from New York State farms, and over half of their whole grains come from Seneca Grain & Bean in Penn Yan, New York, in the neighboring Finger Lakes region.

Stephen Horton mills fresh flour daily at Miller’s Thumb Bakery & Cafe in Buffalo, NY. (Photo credit: Jill Colella)

“Agriculture is a backward business model where you buy all your inputs retail and sell everything wholesale, which is the exact opposite of what a healthy business should do,” says Thor Oechsner, one of the founding partners of Farmer Ground, whose organic Glenn and Warthog wheats make up 80 percent of the Wonderful Loaf. Seeing the success of artisan bakeries like Miller’s Thumb with his products makes Oechsner more optimistic about the market for responsibly grown wheat.

“When we started in 2009, there was a bias against Northeast grains. It took a while to dispel the myth that we couldn’t grow good bread-quality wheats in the Northeast,” says Oechsner, who also operates a 1,200-acre organic farm outside Ithaca, New York. “But now, volume-wise, the commercial artisan bread trade is the largest sector of our business.”

The market for higher quality wheat also shows signs of expanding nationally. According to a report by analysts at Argus Media Group in May, organic wheat production in the U.S. surged 22 percent in 2023-24 from the previous marketing year, driven primarily by dietary shifts and growing consciousness about health. Production is predicted to increase again in 2024-25 to 26.1 million bushels, a 7 percent increase from the prior year. But these markets tend to fluctuate wildly, in the face of stubborn headwinds like rising inflation and unpredictable weather events.

The protectionist trade policies of the incoming Trump administration won’t likely impede sales growth for domestic producers of organic wheat, according to Ryan Koory, an agriculture researcher at Argus. “The impact of any tariff is weighted by the share of supply impacted by that tariff,” he says. “In the case of organic wheat, imports accounted for about 6 percent of U.S. supply over the prior marketing year, a relatively small share.” If imported wheat prices rise due to tariffs, there could be built-in advantages for small bakeries like Miller’s Thumb that rely on domestic producers for their wheat supply, but Koory says it’s too soon to tell.

Restoring the grain economy to its former glory is a tall order. “In the late 19th century, Buffalo was the largest grain port in the world,” says Bruce Jackson, a professor at State University of New York at Buffalo and author of The Life and Death of Buffalo’s Great Northern Grain Elevator.

As the western terminus of the Erie Canal, Buffalo became one of the richest cities in America by the end of the Civil War. The 363-mile manmade canal, which opened in 1825, provided a vital passageway for transporting Midwestern grain, reducing shipping times from Buffalo to New York City from three weeks to just eight days. It was also a boon for factory development along Buffalo’s Belt Line, a 15-mile stretch of commuter and freight rail along which the abandoned Wonder Bread factory still sits.

“One of the key factors in the decline of the grain trade in Buffalo was the development of the St. Lawrence Seaway in 1959,” says Jackson. “It created a much quicker route to the Atlantic, so Buffalo’s shipping industry essentially starved to death.”

In recent years, many architectural achievements from Buffalo’s industrial era have come under assault by corporate interests. In 2022, Archer Daniels Midland, the multinational food processor and commodities trader, razed the Great Northern Elevator, a grain storage facility built here in 1897, despite fervent protests and legal challenges by local advocacy groups like Preservation Buffalo Niagara (PBN). The Great Northern was once the largest grain elevator in the world and the first to be fully powered by electricity.

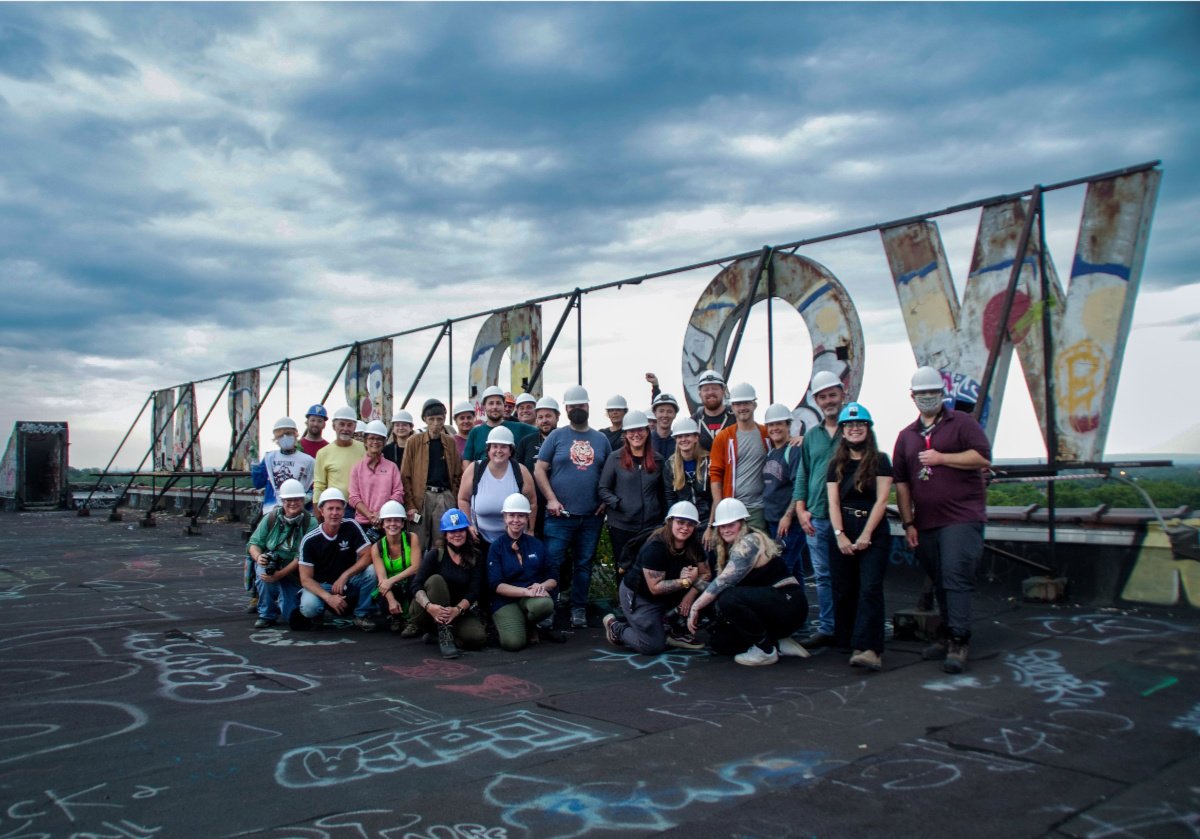

Preservation Buffalo Niagara led a tour of the Wonder Bread factory in August 2024. (Photo courtesy of Emily Jarnot)

This summer, Emily Jarnot, a preservation planner for PBN, led a tour through the abandoned Wonder Bread factory for a group of about 30 locals. She has a personal connection to the product because her uncle Frank worked as the head mixer in the factory for over 25 years before it closed unexpectedly in 2004. Convincing the building’s current owner to grant access for the tour wasn’t easy, and what she found inside was disconcerting. “It was a total mess,” Jarnot says. But, like Hawley, she sees enormous potential in the building as a candidate for preservation.

According to The Buffalo News, the building now faces the threat of demolition, although its owner is trying to find a buyer. Hawley insisted that, regardless of whether the sale goes through, it won’t be easy for anyone to raze the Wonder Bread factory because of its landmark status.

Colella is gravely concerned about the steady erosion of Buffalo’s cultural history, including bread-baking. A giant poster inside the bakery displaying a hand-drawn map of the city’s iconic grain elevators hangs on the wall to remind customers about the city’s distinguished past as a custodian of America’s grain economy. She hopes to develop plans for a food museum in Buffalo that celebrates the city’s agrarian, industrial, and culinary history.

“For a long time, I think Buffalo didn’t know how to tell its own story,” says Colella. “It’s been this joke of a city that doesn’t win Super Bowls, and that’s held it back for quite a long time.” But there are indications that Buffalo is poised for a comeback. In the most recent census, the city’s population grew 6.5 percent, the first increase since 1950 and the most of any city in upstate New York.

These days, young moms and dads with school-age children in tow come into Miller’s Thumb weekly to purchase their Wonderful Loaf, Colella says. She’s encouraged that her vision to deliver a wholesome Wonder Bread alternative to her community has come to fruition. She says that sales are gaining momentum, consistently averaging about 20 to 30 loaves per day.

“There’s a loyal following to that bread,” says Colella. “If we stopped selling it, we would definitely hear about it.”

July 30, 2025

From Oklahoma to D.C., a food activist works to ensure that communities can protect their food systems and their future.

Like the story?

Join the conversation.